COUNTER-FLOW COOLER

Our Counter-Flow Coolers are a critical component in animal feed production lines, designed to cool pellets immediately after the pellet press. At this stage, pellets are hot, moist, and mechanically weak, making cooling essential for product stability and quality.

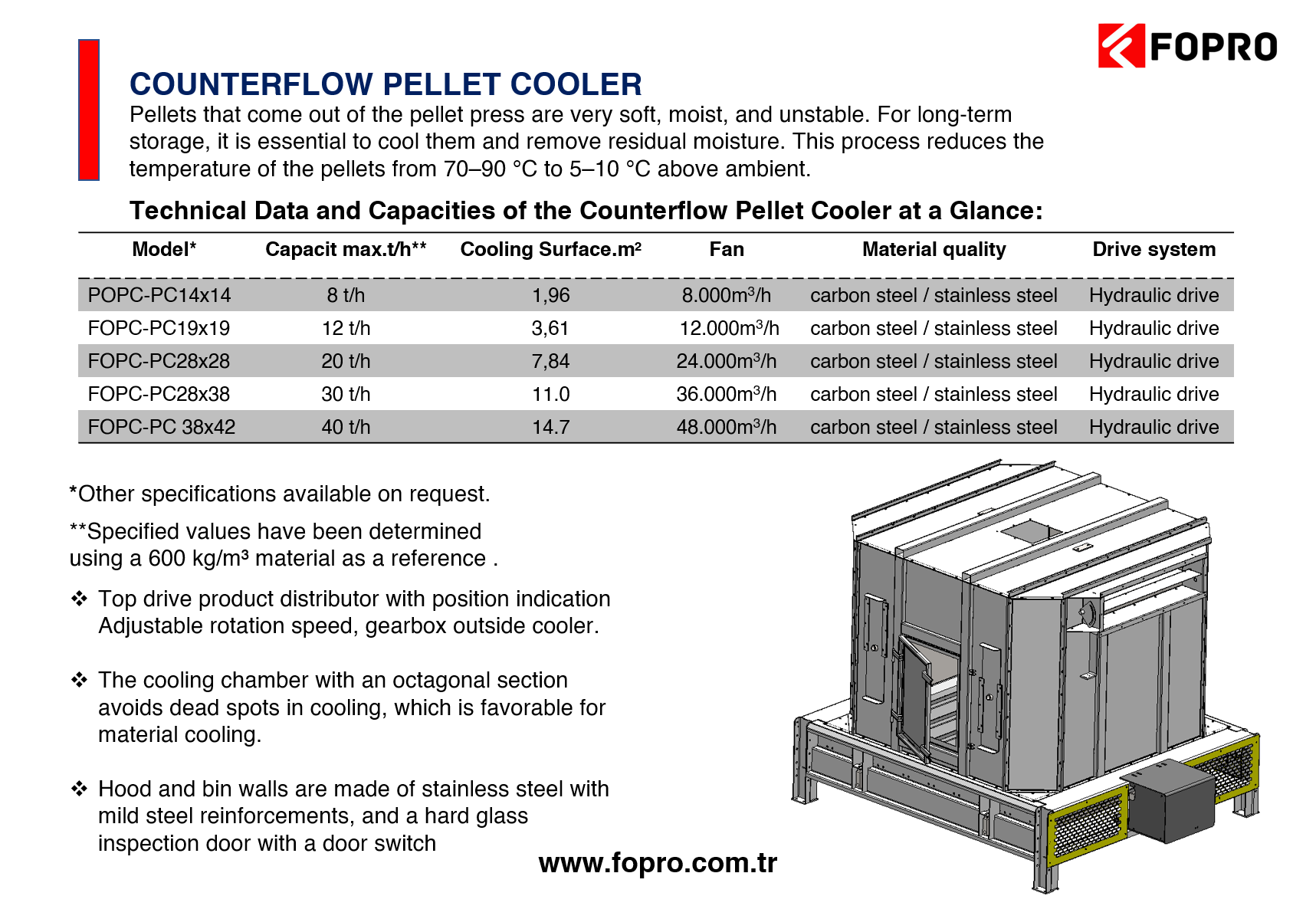

Using a counter-flow air principle, ambient air moves opposite to the pellet flow, ensuring uniform and efficient heat and moisture removal throughout the pellet bed. This process reduces pellet temperature from 70–90 °C to approximately 5–10 °C above ambient while lowering residual moisture content.

Proper cooling improves pellet durability, minimizes fines generation, and ensures safe handling, storage, and packaging. Counter-flow coolers are widely used in animal feed mills to enhance pellet quality, extend shelf life, and ensure reliable downstream conveying and storage.